OUR MISSION

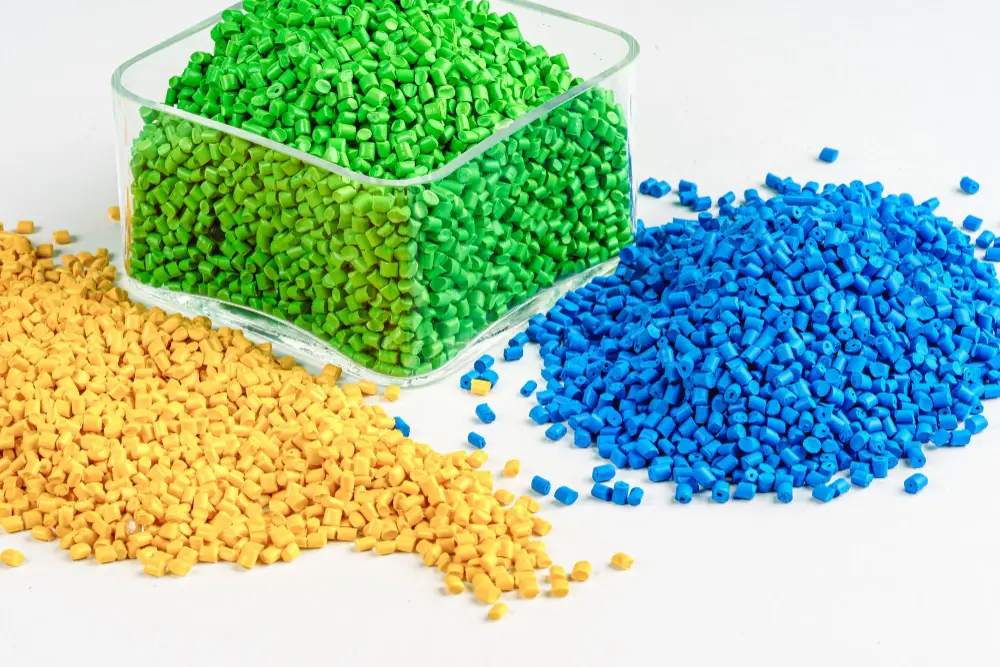

To manufacture and deliver high-quality recycled plastic granules that empower industries to produce durable, sustainable, and cost-efficient products. We are committed to combining advanced technology, consistent quality, and customer-focused service to create materials that drive manufacturing excellence while contributing to a cleaner, greener future.

With over three decades of expertise, Dolphin Polymers has built a trusted name

in recycled polymers. Established in 1986, we continue to lead the industry

through innovation, reliability, and customer satisfaction.

With over three decades of expertise, Dolphin Polymers has built a trusted name

in recycled polymers. Established in 1986, we continue to lead the industry

through innovation, reliability, and customer satisfaction.

Our modern plant integrates cutting-edge technology, ensuring consistent quality

and efficient production of high-performance recycled PP and PPCP granules.

Our modern plant integrates cutting-edge technology, ensuring consistent quality

and efficient production of high-performance recycled PP and PPCP granules.

We ensure moisture resistance, durability, accurate composition, and vibrant

color consistency — tested against domestic and international quality standards.

We ensure moisture resistance, durability, accurate composition, and vibrant

color consistency — tested against domestic and international quality standards.

Our commitment to sustainability drives us to recycle plastic waste into

high-performance granules, reducing global landfill pressure and supporting a

circular economy.

Our commitment to sustainability drives us to recycle plastic waste into

high-performance granules, reducing global landfill pressure and supporting a

circular economy.

We provide tailor-made polymer solutions, ensuring on-time delivery and

dedicated support to meet every client’s unique requirements worldwide.

We provide tailor-made polymer solutions, ensuring on-time delivery and

dedicated support to meet every client’s unique requirements worldwide.